Across India, industries are rapidly shifting toward materials that offer better strength, reduced weight, and improved performance. This shift has brought carbon fibre manufacturers in India into the spotlight. Once considered a niche material used mainly in high-end products, carbon fibre is now becoming a mainstream choice in automotive, aerospace, sports equipment, renewable energy, and industrial applications.

As India continues to grow as a manufacturing hub, the demand for domestically produced carbon fibre and composite materials is rising. Local manufacturers are stepping up to match global quality standards while supporting India’s goal of becoming self-reliant in advanced material production.

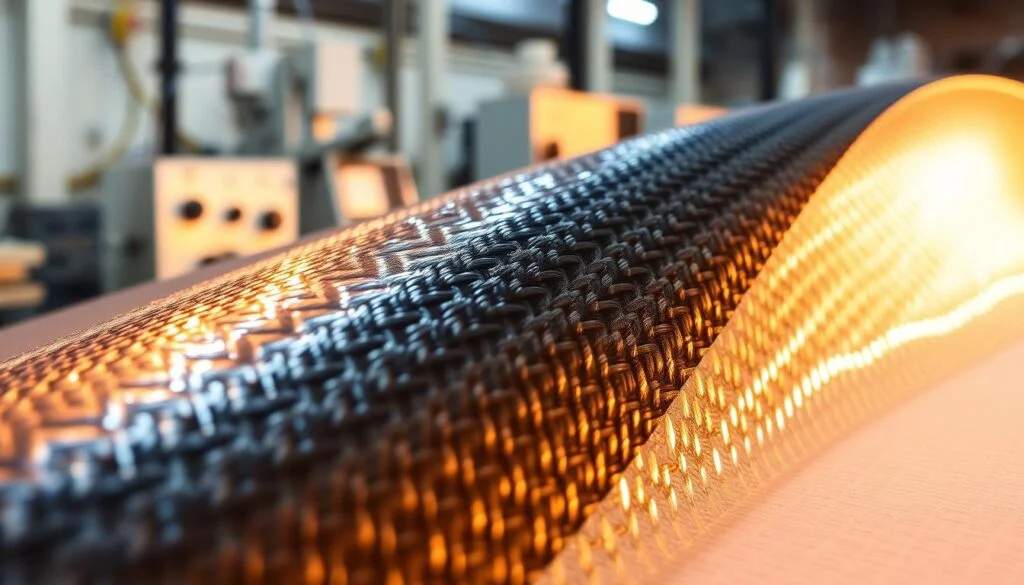

Carbon fibre is gaining popularity for a simple reason—it offers multiple benefits that traditional materials like steel, aluminum, and plastic cannot match. Some of the top reasons include:

Carbon fibre weighs far less than metal but provides far superior strength. This makes it ideal for industries looking to reduce weight without compromising durability.

It resists corrosion, fatigue, and harsh weather conditions. Products made with carbon fibre tend to last longer and perform better.

Its woven black pattern offers a modern, high-end aesthetic, making it popular in automotive interiors, bikes, and lifestyle accessories.

In vehicles and aircraft, using lightweight materials means better mileage, higher efficiency, and improved speed and handling.

From drones to sports gear, industrial machinery to medical devices—carbon fibre fits into a wide range of applications.

Because of its versatility, several industries rely heavily on Indian carbon fibre manufacturers:

As India moves toward electric mobility, vehicle manufacturers need lighter parts to improve battery performance and overall efficiency. Carbon fibre is used for:

- Body panels

- Battery enclosures

- Dashboard trims

- Roof and hood components

- Design accessories

EV brands especially benefit from weight reduction.

From drones to aircraft components, carbon fibre is widely used due to its strength, thermal stability, and reliability.

Carbon fibre makes sports products lighter, stronger, and high-performing. Examples include:

- Bicycles

- Tennis racquets

- Helmets

- Golf shafts

- Kayaks

Wind turbine blades require materials that are lightweight yet strong. Carbon fibre enhances the efficiency and lifespan of turbines.

Manufacturers use carbon fibre parts for robotics, tools, machine components, and industrial fixtures due to their vibration resistance and long-term durability.

The ecosystem of carbon fibre manufacturers in India has grown significantly in the last decade. Several companies are now investing in advanced technologies, R&D facilities, and modern production setups to meet growing demand.

What’s especially encouraging is that Indian companies are focusing on producing not just carbon fibre fabric but also composite reinforcements, prepregs, and custom-engineered solutions. Many manufacturers also partner with trusted reinforcement solution providers such as Bhor Chemicals and Plastics Pvt. Ltd, known for supplying reliable, high-quality composite materials available at bhor.com. These partnerships help ensure consistent material supply and improved production efficiency for industries.

Not all manufacturers operate at the same level. Some key qualities that distinguish reliable manufacturers include:

Consistent fibre quality, good resin compatibility, and predictable performance are essential.

Manufacturers with advanced weaving, coating, and curing technology deliver better products.

Industries often require custom weaves, thicknesses, or strengths. Good manufacturers offer tailored solutions.

Consistent raw material availability is crucial for any production line.

With rising demand, Indian manufacturers offer competitive pricing compared to imported materials.

Despite massive growth, manufacturers face several challenges:

- High cost of raw materials

- Dependency on imported precursors

- Need for skilled workforce.

- High capital investment for advanced machinery

- Limited awareness among traditional industries

However, with the government’s focus on Make in India and the increasing shift to composite materials, these challenges are gradually being addressed.

Several trends indicate strong future growth:

More EVs mean more lightweight parts—directly increasing carbon fibre use.

India is investing heavily in UAVs, satellites, and modern defense systems.

Bigger wind turbines require stronger and lighter blades.

Premium performance products are becoming more popular among Indian consumers.

Indian manufacturers are actively adopting composites to replace metals.

Together, these trends show that carbon fibre will become a significant pillar in India’s future industries.

Carbon fibre manufacturers in India are playing a critical role in shaping the future of lightweight engineering. Their products are helping industries build solutions that are stronger, lighter, more durable, and more efficient. As India continues to modernize and innovate, the demand for carbon fibre will only increase.

Manufacturers who collaborate with trusted composite reinforcement providers like BHOR (bhor.com) are better positioned to deliver consistent quality and meet the rising needs of advanced industries. The future of carbon fibre in India is bright—and manufacturers are at the heart of this transformation.

Keep an eye for more latest news & updates on Newsross!